Applicable Reverse Engineering Upgrades to Endodontic Shaping Systems Soon After the Establishment of Universal Standards for Fatigue Test Condition

By Dr. Ekim Onur Orhan

This short note highlights the need for a standardization regarding endodontic shaping systems, able to predict their remaining functional life. The objective is to reduce the risk of failure by optimally deciding the time in which the shaping instrument must be substituted. This approach is much used in industry and especially inexpensive machines with a well-rooted and largely developed discipline known as predictive maintenance. When universal standardization is succeeded in the fatigue tests of shaping instruments, any technique used today in predictive maintenance of the remaining functional life of rotary instruments can be easily adapted for this purpose. Possible failure modes of each instrument should be identified using a failure mode effect analysis (FMEA) that is today standard. Also, and for each of such possible models, the most informative variables to monitor must be detected, as well as how they will be monitored, and finally, a prediction of the lifespan according to specific tests for each failure mode of each specific sort of instrument or alloy. The letter purely focused on the need for failure model standardization as an essential prerequisite. The letter also includes very general and well-known comments for predictive maintenance.

This short note highlights the need for a standardization regarding endodontic shaping systems, able to predict their remaining functional life. The objective is to reduce the risk of failure by optimally deciding the time in which the shaping instrument must be substituted. This approach is much used in industry and especially inexpensive machines with a well-rooted and largely developed discipline known as predictive maintenance. When universal standardization is succeeded in the fatigue tests of shaping instruments, any technique used today in predictive maintenance of the remaining functional life of rotary instruments can be easily adapted for this purpose. Possible failure modes of each instrument should be identified using a failure mode effect analysis (FMEA) that is today standard. Also, and for each of such possible models, the most informative variables to monitor must be detected, as well as how they will be monitored, and finally, a prediction of the lifespan according to specific tests for each failure mode of each specific sort of instrument or alloy. The letter purely focused on the need for failure model standardization as an essential prerequisite. The letter also includes very general and well-known comments for predictive maintenance.

Endodontic engine-driven shaping systems facilitate root canal preparation. Root canal shaping with engine-driven nickel-titanium (r-NiTi) instruments has been reported to cause significantly lesser canal transportation or other shaping errors than conventional hand instruments1. Currently, evidence-based flexible alloys, motion kinematics, and appropriate designs have been successfully integrated into endodontic shaping instruments2. On the other hand, fatigue-related separation is still one of the failure causes of engine-driven endodontic instrument failures3. The instrument fragment tip could lead to a more complicated status of the cleaning and disinfection procedures4. The usage‐induced degradation of different r-NiTi instruments has been well-reported in a study5. However, both single-use and multiple-use recommended shaping systems are available in dental markets6. The underlying strategy of disposable r-NiTi is to prevent usage‐induced degradation or failures5. Reuse of the disposable instrument is inevitably the responsibility of the practitioners. A practitioner can influence the functional life of instruments as a function of the rotational speed7, the type of kinematic8, the pre-flaring procedures9, glide path preparation10, the number of uses11, and sterilization cycles13.

If any r-NiTi instrument exceeds the individual ultimate deformation limits, separation occurs13. This hypothesis has been tested on the r-NiTi instrument with a plethora of studies14. The reported incidence of r-NiTi file separation is highly variable (0.14–5%). The influenced factors to the separation have been determined in the previous studies: Study design, number and kind of teeth included, operator experience, instrument type, single- or multi-use of instruments, and metallurgy15-17. On the other hand, patient-centered factors such as root canal anatomy with its inherent angle and radius of the curvature are constant7.

Current international standards for endodontic instruments do not fully elaborate the ideals for fatigue test condition18. The influence between the congruency of instrument outer geometry and canal simulation has been reported in a recent study19. To provide uniformity of methodology and to enable comparable results, the authors have justified the need for standardization for cyclic fatigue testing of r-NiTi instruments19. The authors have been proposed a collective parameter sequence for experimental setups of universal cyclic fatigue testing19. The parameters should be considered as a single virtual condition of root canal anatomy; therefore, it should be multiplied by both worse and better complications. Thus, r-NiTi instruments are able to be universally compared at different virtual condition.

Predictive maintenance is one of the main subjects of process improvements in process management. The major benefit of predictive maintenance is to prevent unexpected equipment failures due to allowing appropriate scheduling of corrective maintenance. The main components of predictive maintenance are data collection and preprocessing, early fault detection, fault detection, time to failure prediction, maintenance scheduling, and resource optimization20,21. The failure mode and effect analysis (FMEA) is a multistep approach for identifying all potential failures in a design, a manufacturing or an assembly process, or a service. Accordingly, FMEA is one of the risk assessment methods recommended by international standards in the process analysis22. Principally, the purpose of FMEA applications is to prevent or decrease errors in adapted sectors23. Especially, aeronautical engineering technology is the best representative application of such analyses24. In an example of FMEA, the replacement time for each mechanical part of an aircraft has already been formerly calculated according to the specific international standards before its operation. Therefore, each sort of mechanical component of an aircraft is renewed, when its time is up without occurring any failure in the maintenance period.

‘Life data analysis’ or ‘Weibull analysis’25 is frequently used to provide predictions about the cyclic fatigue lifespan of r-NiTi instruments in endodontics26-30. Nguyen et al. 31 have reported that the Weibull reliability was a suitable method to interpret the probability of survival for NiTi files. Similarly, Iacono et al. 30 have reported the estimation of fatigue life of WaveOne & WaveOne Gold (Dentsply-Sirona, Baillagues, Switzerland) and Reciproc & Reciproc Blue (VDW GmbH, Munich, Germany) instruments using the Weibull analysis. The Weibull modulus, characteristic life, and the predicted maximum cycles for 99% probability of survival calculate using Equation 1:

![]()

Ps shows the survival probability, σ is the number of cycles to fracture (NCF) at a given Ps, and σ0 is the characteristic life29,31. The high reliability for an r-NiTi instrument correlates with the high Weibull modulus29,31. Therefore, a high anticipated number of cycles until failure is related to high-reliability29,30. If the aforementioned fatigue test model standardization is provided universally, the calculation of the estimated cyclic lifespan of an r-NiTi instrument before occurring failure is applicable with the adaption of current predictive maintenance tools.

In a recent study, root canal treatment has been defined as complex. Also, a sense of lack of control has been reported during the steps of endodontic treatment by practitioners32. This is well-known that many works, journals, and researchers are continuously providing new insights and tools to improve general and specific applications. To meet such challenges, many studies, journals, and researchers continually offer new insights and tools, developing general and specific practices. The content of this letter might be considered as being a personal opinion of an expert in the Endodontology field. If the border of the relevant standardization is expanded and the relevant data is released from the manufacturers, the outcomes of the applicable upgrades will be demonstrated in scientific studies that will undergo peer-reviewing in the future.

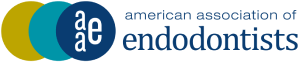

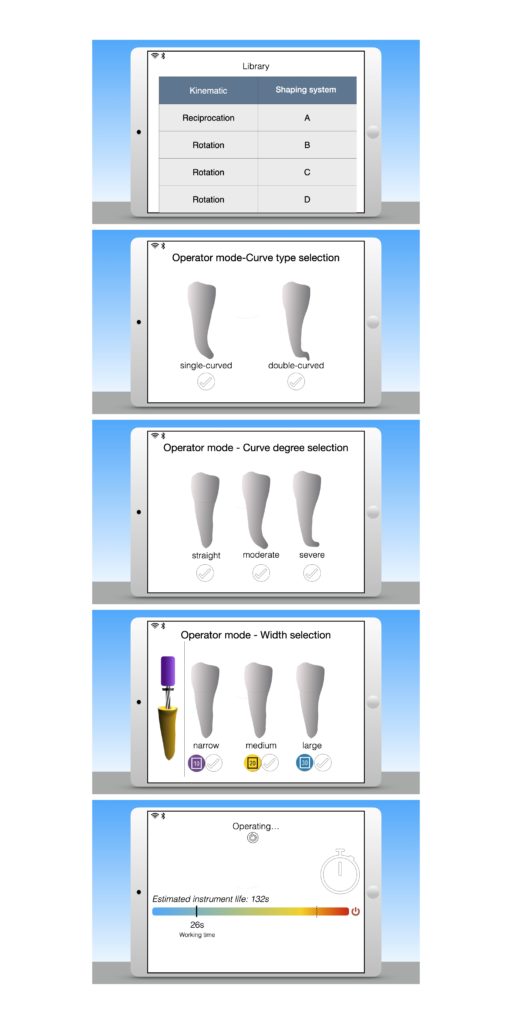

For now, the current datasets and reported Weibull distributions of cyclic fatigue resistance in r-NiTi instruments are not appropriate to predict failure after a specific period. Although clinicians are not familiar with reverse-engineering techniques, the opinions and illustrations noted in this letter may be beneficial in solving the problem of a well-known instrument fracture as a complication of root canal shaping Figures 1 and 2. Mainly, this information is for the research and development division of manufacturers, which should be responsible for including such informatics software tools in their endodontic products when relevant universal standards exist.

References

1. Schafer E, Lohmann D. Efficiency of rotary nickel- titanium FlexMaster instruments compared with stainless steel hand K-Flexofile – Part 1. Shaping ability in simulated curved canals. Int Endod J. 2002;35:505–513.

2. Ounsi HF, Nassif W, Grandini S, et al. Evolution of nickel-titanium alloys in endodontics. J Contemp Dent Pract. 2017;18:1090-1096.

3. McGuigan MB, Louca C, Duncan HF. Clinical decision-making after endodontic instrument fracture. Br Dent J. 2013;214:395-400.

4. Solomonov M, Webber M, Keinan D. Fractured endodontic instrument: a clinical dilemma retrieve, bypass or entomb? New York State Dental Journal. 2014;80:50–2.

5. Bhatia S, Nagendrababu V, Peters OA, et al. Evaluation of usage-induced degradation of different endodontic file systems. Sci Rep. 2021 27;11:9027.

6. Deniz N, Orhan EO. Development of a multi-criteria decision-making-based assessment model for dental material selection: Engine-driven nickel-titanium instruments case study. Clin Oral Investig. 2021 Nov 8. doi: 10.1007/s00784-021-04234-7. Epub ahead of print.

7. Zelada G, Varela P, Martín B, et al. The effect of rotational speed and the curvature of root canals on the breakage of rotary endodontic instruments. J Endod. 2002;28:540–542.

8. Ferreira F, Adeodato C, Barbosa I, et al. Kinematics and cyclic fatigue of NiTi rotary instruments: A systematic review. Int Endod J. 2017;50:143–152.

9. Roland DD, Andelin WE, Browning DF, et al. The effect of preflaring on the rates of separation for 0.04 taper nickel titanium rotary instruments. J Endod. 2002;28:543–545.

10. Patiño PV, Biedma BM, Liébana CR, et al. The influence of manual glide path on the separation rate of NiTi rotary instruments. J Endod. 2005;31:114–116.

11. Parashos P, Gordon I, Messer HH. Factors influencing defects of rotary nickel-titanium instruments after clinical use. J Endod. 2004;30:722–725.

12. Hilfer PB, Bergeron BE, Mayerchak MJ, et al. Multiple autoclave cycle effects on cyclic fatigue of nickel-titanium rotary files produced by new manufacturing methods. J Endod. 2011;37:72–74.

13. Di Fiore PM. A dozen ways to prevent nickel-titanium rotary instrument fracture. J Am Dent Assoc. 2007;138:196–201.

14. Hülsmann M, Donnermeyer D, Schäfer E. A critical appraisal of studies on cyclic fatigue resistance of engine-driven endodontic instruments. Int Endod J. 2019;52:1427-1445.

15. Bueno CSP, Oliveira DP, Pelegrine RA, et al. incidence of WaveOne Gold files: A prospective clinical study. Int Endod J. 2020;53:1192–1198.

16. Caballero-Flores H, Nabeshima CK, Binotto E, et al. Fracture incidence of instruments from a single-file reciprocating system by students in an endodontic graduate program: A cross-sectional retrospective study. Int Endod J. 2019;52:13–18.

17. Coelho MS, Rios MA, Bueno CEDS. Separation of nickel-titanium rotary and reciprocating instruments: a mini-review of clinical studies. Open Dent J. 2018;12:864–872.

18. International Organization for Standardization. International Standard ISO 3630-1:2019(E): Dentistry—Endodontic Instruments— Part 1: General Requirements, 3rd ed.; International Organization for Standardization: Geneva, Switzerland, 2019.

19. Bürklein S, Maßmann P, Donnermeyer D, et al. Need for standardization: influence of artificial canal size on cyclic fatigue tests of endodontic instruments. Appl Sci. 2021;11: 4950.

20. Goriveau R, Medjaher K, Zerhouni N. From prognostics and health systems management to predictive maintenance 1: monitoring and prognostics. ISTE Ltd and John Wiley & Sons, Inc. 2016.

21. Mobley, R. Keith. An introduction to predictive maintenance (2nd ed.). Butterworth-Heinemann. 2002. pp. 4–6.

22. ISO 9001. Quality management systems: requirements. 4th ed. Geneve: International Organization for Standardization; 2008. pp.1-27.

23. Mascia A, Cirafici AM, Bongiovanni A. et al. A failure mode and effect analysis (FMEA)-based approach for risk assessment of scientific processes in non-regulated research laboratories [Internet]. Accredit Qual Assur 2020 [accessed 2022 Jan 22]. Available from: https://doi.org/10.1007/s00769-020-01441-9.

24. Johnson M. Using process FMEA in an aeronautical engineering technology capstone course [Internet]. Engineering 2010 [Accessed 2022 Jan 22]. Available from: https://pdfs.semanticscholar.org/e4e0/16521f3583eb4629f7c8b286406d59c86267.pdf?_ga=2.84837465.196091742.1603376919-343994430.1551358764.

25. Weibull W. A statistical distribution function of wide applicability. J Applied Mechanics. 1951;128:293-297.

26. Klocke A, Kahl‐Nieke B. Influence of force location in orthodontic shear bond strength testing. Dent Mater. 2005;21:391-396.

27. Arias A, Perez‐Higueras JJ, de la Macorra JC. Differences in cyclic fatigue resistance at apical and coronal levels of Reciproc and WaveOne new files. J Endod. 2012;38:1244-1248.

28. Arias A, Perez‐Higueras JJ, de la Macorra JC. Influence of clinical usage of GT and GTX files on cyclic fatigue resistance. Int Endod J. 2014;47:257-263.

29. Elsaka SE, Elnaghy AM. Cyclic fatigue resistance of OneShape and WaveOne instruments using different angles of curvature. Dent Mater J. 2015;34:358-363.

30. Iacono F, Pirani C, Arias A, et al. Impact of a modified motion on the fatigue life of NiTi reciprocating instruments: a Weibull analysis. Clin Oral Invest. 2019;23:3095-3102.

31. Nguyen HH, Fong H, Paranjpe A, et al. Evaluation of the resistance to cyclic fatigue between ProTaper Next, ProTaper Universal, and Vortex Blue rotary instruments. J Endod. 2014;40:1190-1193.

32. Dahlström L, Lindwall O, Rystedt H, et al. ‘Working in the dark’: Swedish general dental practitioners on the complexity of root canal treatment. Int Endod J. 2017;50:636-645.

Figure 1. A fictional illustration of input interfaces of remaining functional life calculator software (at operator selection mode).

Figure 2. A fictional illustration of input interfaces of remaining functional life calculator software (at artificial intelligence mode).

Dr. Ekim Onur Orhan is a professor (associate) at Department of Endodontics, Faculty of Dentistry, Eskişehir Osmangazi University, Turkey. Dr. Orhan can be reached at ekimonurorhan@gmail.com or +90 222 239 3750.